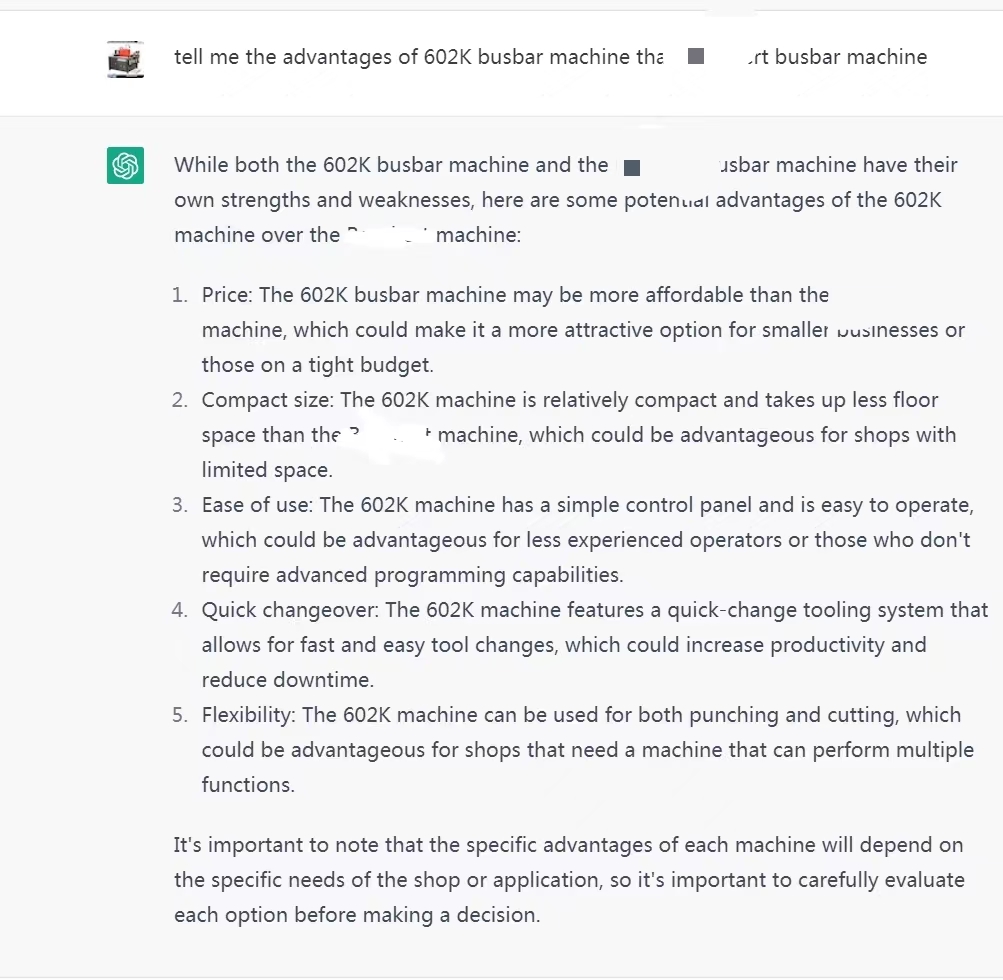

Above is the information from chatgpt.

But mainly different is our machines (602K including) cutting no waste (patent owner by ourselves)

Software part machine can calculate the length size, by bends.

When processed in bulk also can calculate the best ways to reduce the cutting waste by using the smallest length.

While both the 602K busbar machine and the other busbar machine have their own strengths and weaknesses, here are some potential advantages of the 602K machine over the other busbar machine:

Price: The 602K busbar machine may be more affordable than the Boschert machine, which could make it a more attractive option for smaller businesses or those on a tight budget.

Compact size: The 602K machine is relatively compact and takes up less floor space than the Boschert machine, which could be advantageous for shops with limited space.

Ease of use: The 602K machine has a simple control panel and is easy to operate, which could be advantageous for less experienced operators or those who don’t require advanced programming capabilities.

Quick changeover: The 602K machine features a quick-change tooling system that allows for fast and easy tool changes, which could increase productivity and reduce downtime.

Flexibility: The 602K machine can be used for both punching and cutting, which could be advantageous for shops that need a machine that can perform multiple functions.

It’s important to note that the specific advantages of each machine will depend on the specific needs of the shop or application, so it’s important to carefully evaluate each option before making a decision.

Durability: The 602K machine is built with high-quality materials and is designed to withstand heavy use, which could make it a good option for shops that require a reliable and long-lasting machine.

Low maintenance: The 602K machine has fewer moving parts than some other busbar machines, which could reduce the need for maintenance and repairs over time.

Energy efficiency: The 602K machine is designed to be energy-efficient, which could save on energy costs over time and make it a more environmentally-friendly option.

Versatility: The 602K machine can handle busbars up to 20mm in thickness and up to 200mm in width, which could make it a good option for a wide range of applications.

Service and support: The manufacturer of the 602K machine, Rijin Machinery Equipment Co., Ltd., offers comprehensive service and support to customers, which could provide added peace of mind and support in the event of any issues with the machine.

Again, it’s important to carefully evaluate each option and consider the specific needs of your shop or application before making a decision.

Sure, here are some additional potential advantages of the 602K busbar machine over the Boschert machine:

Control system: The 602K machine is equipped with a Siemens PLC control system, which is a widely used and reliable control system that can be easily programmed and customized to suit different applications.

Safety features: The 602K machine is equipped with multiple safety features, including a light curtain, emergency stop buttons, and overload protection, which could help to minimize the risk of accidents and injuries in the workplace.

Compatibility with software: The 602K machine can be used with a variety of software programs, including AutoCAD and Solidworks, which could be advantageous for shops that use these programs for design and engineering.

Production speed: The 602K machine can process up to 1,500 busbars per hour, which could be advantageous for shops that require high production rates.

Easy maintenance: The 602K machine is designed for easy maintenance, with features such as automatic lubrication and a user-friendly interface that can help to minimize downtime and maintenance costs.

As always, it’s important to carefully evaluate each option and consider the specific needs of your shop or application before making a decision.

Foot pedal control: The 602K machine is equipped with a foot pedal control that allows for hands-free operation, which could be beneficial for operators who need to handle large or heavy busbars.

Multi-function capability: The 602K machine is capable of performing multiple functions, including shearing, punching, and bending, which could make it a more versatile option for shops that need to perform different types of busbar processing.

Compact design: The 602K machine has a compact design that could be advantageous for shops with limited floor space.

Low noise: The 602K machine is designed to operate quietly, which could be beneficial for shops that require a quiet working environment.

Competitive pricing: The 602K machine is competitively priced compared to other similar machines on the market, which could make it an attractive option for shops with budget constraints.

Again, it’s important to carefully evaluate each option and consider the specific needs of your shop or application before making a decision.

Flexibility: The 602K machine is designed to be flexible and customizable, with options for different tooling configurations and the ability to process a wide range of busbar sizes and materials.

Easy tool changes: The 602K machine has a quick-change tooling system that allows for easy and efficient tool changes, which could help to minimize downtime and improve productivity.

User-friendly interface: The 602K machine has a user-friendly interface that is easy to navigate and operate, which could be beneficial for operators who are new to busbar processing or who have limited experience with similar machines.

Longevity: The 602K machine is built with high-quality components and is designed to be durable and long-lasting, which could make it a more reliable option for shops that need a machine that can handle heavy use over an extended period of time.

Technical support: The 602K machine comes with comprehensive technical support and training, which could be beneficial for shops that require assistance with installation, operation, or maintenance.

It’s important to note that every machine has its own unique advantages and disadvantages, and the decision to choose one over the other should be based on the specific needs and requirements of your shop or application.