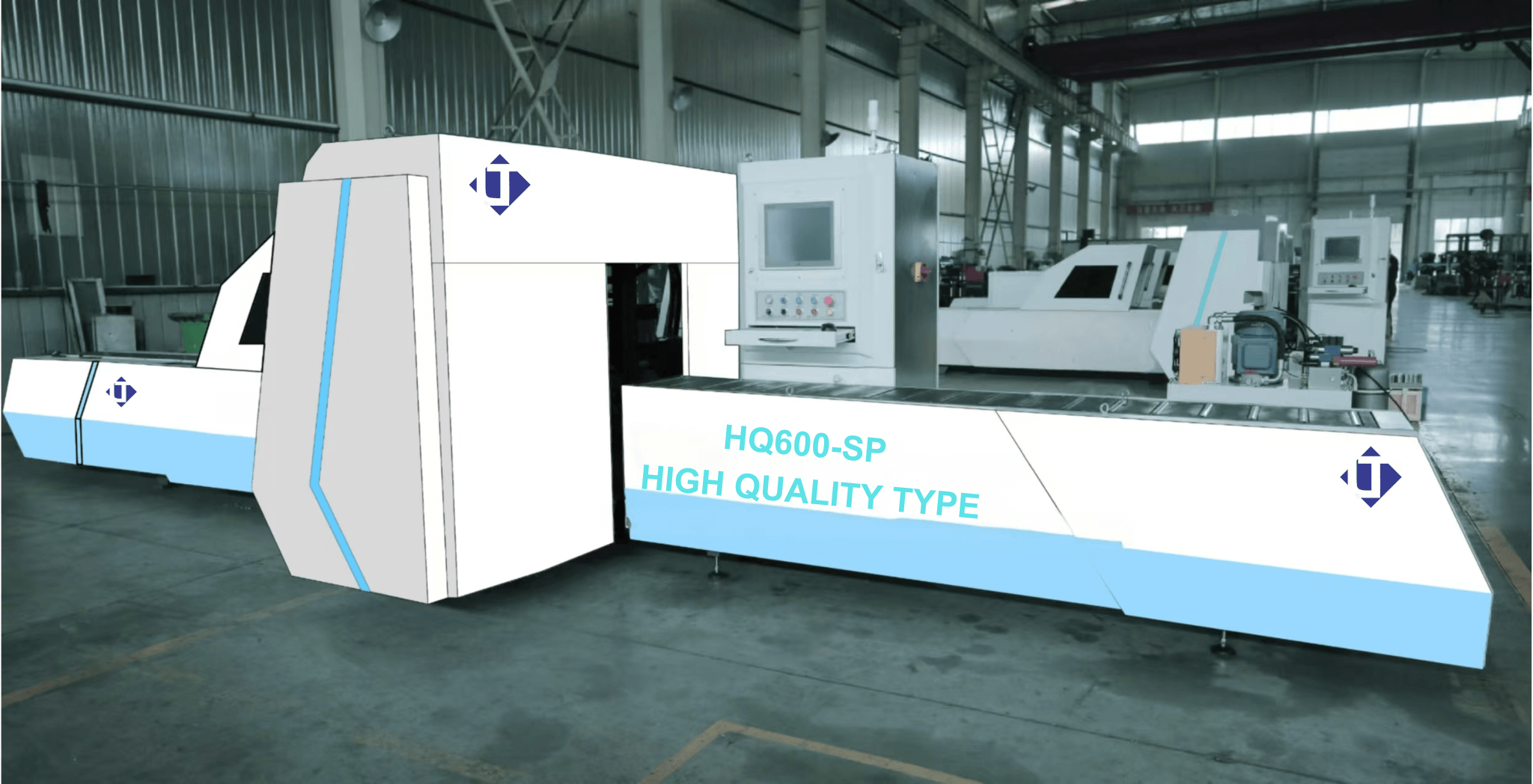

303U-3-C Busbar Machine for cutting Bending and Punching

Price 5,000$-17,000$. (According to different axe, power, and parts… prices are much different).

The 303U-3-C busbar machine for cutting punching bending can punch, shear, bend, emboss, chamfer, twist, press, and press cable tread processing.

The 303U-3-C busbar machines for cutting punching bending (also known as busbar machine, busbar machinery, busbar processing machine, or copper busbar processing machine) are mainly used for various specifications of copper, and aluminum busbar processing.

The machine can respectively or simultaneously punch, shear, and bend processing.

It is a simple operation, convenient to use, and has high production efficiency.

It is specially used for the power industry, high and low-voltage complete sets. And the busbar industry processing copper and aluminum busbar special equipment.

303U-3-C

303U-3-C

Main functions of 303U-3-C busbar machine for cutting bending and punching :

Cutting, punching, bending (vertical bending, flat bending, u bending, offset bending), twisting chamfering, embossing (various circular holes, square holes, special-shaped holes, and groove shapes), and other processing of copper and aluminum busbars.

It is a simple operation, and convenient to use. And it is high production efficiency. The busbar machine for cutting bending and punching is specially used for the power industry, high and low voltage complete sets, and busbar industry processing copper and aluminum busbar special equipment.

The main features of the busbar machine for cutting punching bending:

- The 303U-3-C busbar machine for cutting punching bending has three processing units punching, cutting, and bending, which can respectively carry out the punching, cutting, and bending processing of the bus bar. You can also choose the special processing of flattening , embossing, pressing cable joints, buttons, and so on.

- The 303U-3-C busbar machine for cutting punching bending adopts the double-layer workbench design scheme, three stations can work at the same time without affecting each other, is easy to use, and production efficiency is obviously higher than the traditional busbar processing equipment.

- The working stroke of each unit can be conveniently adjusted to reduce processing auxiliary time and improve production efficiency.

- Punching and shearing unit with vertical processing, flexible and convenient operation, shear using flat shear or punching shear, shear workpiece flat.

- The bending unit is horizontal, and the bending of flat and vertical bending can be achieved by replacing the mold. The bending unit of the CNC busbar processing machine adopts numerical control mode and has a memory function.

- Through the replacement of the mold can also achieve a variety of processing functions, such as embossing, flattening, pressing cable joints and button twists, etc.

- The punching unit of the turret busbar processing machine adopts the turret structure, which can assemble 4/6/8 sets of punching dies at one time. Can choose the appropriate punching mold to work, a simple operation.

Main advantages of our 303U-3-C busbar cutting bending and punching machine:

- The cutting unit adopts a double-column shear structure (patent number: ZL201120262802.1), Cut mouth flat, no burr, and no waste.

- The punching unit adopts Nodular cast iron, 4/6/8 modes position turret punching structure which is a total whole one, improving the concentric degree of molds,

prolonging the service life of the molds, saving time for a change.

- The bending unit adopts a closed bending structure, making it more uniform when processing horizontal bending and embossing. Also prolonging the service life.

- The bending unit adopts a double work table, achieving a real sense of the three positions working at the same time while working without impacting each other.

- Adopting PLC controlled, the bending angle can be CNC controlled and with a storage function.

- Three units of the machine can work at the same time, not affecting each other, improving the processing efficiency.

- Hydraulic tank with thick plate welding, and is treated by phosphating, making hydraulic oil can be long time used and will not degenerate.

Bidirectional positioning:

The perfect combination of bidirectional positioning design of the punching station and table scale makes the busbar punch more accurate, improves work efficiency, and reduces the generation of defective products.

Imported Siemens PLC:

Adopt imported Siemens PLC to ensure the safety and stability of the circuit.

Avoid machine failure, more durable.

Strong driving force:

Three power motors are used.

Ensure the dynamic stability of the three stations and that each of them does not interfere with the other.

Touch control screen:

The touch control screen, and intelligent control system accurately set parameters to achieve intelligent control.

Hydraulic tank special treatment:

The 3mm thick steel plate is welded and treated with phosphating to prevent pollution and corrosion of hydraulic oil.

DGWMX303E-3-S busbar machine for cutting punching bending

Main parts of the CNC busbar procesing machine